Bayside Laser Things To Know Before You Get This

Table of ContentsGetting My Bayside Laser To WorkSome Known Questions About Bayside Laser.The Greatest Guide To Bayside LaserThe Of Bayside LaserFascination About Bayside LaserBayside Laser for Beginners

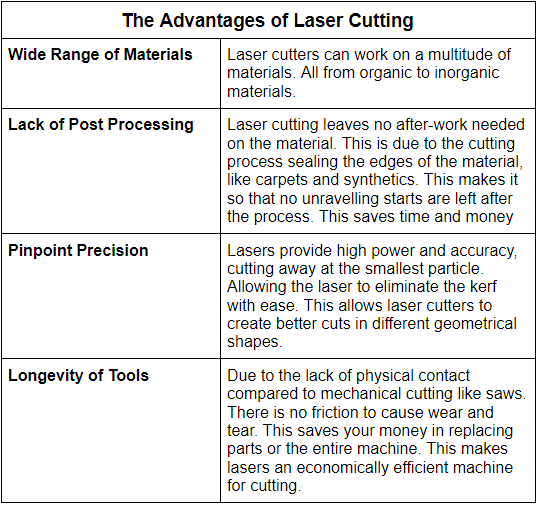

lasers impress because of how little sound they produce. lasers vaporise material with the packing as well as focus of light. This indicates no chips are developed. That indicates offices stay clean as well as sanitary. Your employees don't then need to tidy up chips, that makes the procedure dramatically quicker as well as more effective.This means that the area around the cut continues to be undamaged, also with deep cuts. The material will certainly not be harmed or distorted.

Low-wear and low-maintenance laser reducing means there is practically no loss of top quality, and also the outcomes always thrill with their optimum accuracy! (https://dribbble.com/ba7sid3laser/about).

Traditional industrial handling requires some prep work before cutting the job piece. The laser reducing device makes use of computer control technology to recognize reducing.

10 Simple Techniques For Bayside Laser

The laser cutting equipment can considerably reduce the handling time. In terms of handling effect, the reducing surface area of the job piece after cutting by the device is rough and unequal.

The operation of cutting processing is straightforward. CNC laser cutters have little slits. It can perform difficult cutting of small parts.

The Bayside Laser Statements

DXTECH laser cutting equipments can not just cut numerous different materials however additionally have great convenience to use. If you desire to recognize more advantages of the laser cutter or other aspects of laser makers, just contact us.

This machine was made by the Western Electric Engineering Proving Ground. In 1967, the British spearheaded laser-assisted oxygen jet reducing for steels. In the very early 1970s, this innovation was placed into production to cut titanium for aerospace applications. At the exact same time, CO2 lasers were adapted to cut non-metals, such as textiles, because, at the time, CO2 lasers were not effective enough to get rid of the thermal conductivity of metals.

With a wavelength of only 1064 nanometers fiber lasers produce an incredibly tiny area dimension (approximately 100 times smaller sized contrasted to the CO2) making it optimal for cutting reflective steel product. This is just one of the major benefits of Fiber compared to CO2 - metal laser cutting. Fibre laser cutter benefits consist of:- Fast handling times.

Bayside Laser - The Facts

Thaw as well as blow or combination cutting uses high-pressure gas to blow liquified product from the cutting area, significantly lowering the power demand. The material is heated up to melting factor then a gas jet strikes the molten material out of the kerf preventing the demand to raise the temperature of the material any even more.

Breakable materials are especially sensitive to thermal fracture, a function manipulated in thermal stress splitting. A beam of light is concentrated on the surface causing local home heating and also thermal growth. This results in a crack that can then be led by relocating the light beam. The split can be relocated order of m/s. https://codepen.io/ba7sid3laser/pen/MWzGBaQ.

If the cutting head may be managed, it is assigned as the Z-axis. Relocating product lasers have a stationary reducing head as well as move the material under it.

This design of equipment often tends to have the least light beam delivery optics yet additionally tends to be the slowest. Crossbreed lasers supply a table that moves in one axis (usually the X-axis) and also relocates the head along the much shorter (Y) axis. This results in an extra continuous beam distribution path length than a flying optic maker and might allow an easier beam of light distribution system.

How Bayside Laser can Save You Time, Stress, and Money.

53 inches (3876 mm). Advantages of laser cutting over mechanical cutting consist of simpler work holding as well as reduced contamination of workpiece (because there is no reducing side which can become polluted by the product or contaminate the material). Precision might be far better because the laser beam does not put on throughout the procedure.

With a wavelength of just 1064 nanometers fiber lasers produce an extremely tiny area dimension (up to 100 times smaller contrasted to the carbon dioxide) making it suitable for reducing reflective metal product. This is among the primary benefits of Fiber contrasted to carbon dioxide. Fiber laser cutter advantages consist of:- Fast processing times.

Thaw as well as blow or combination cutting uses high-pressure gas to blow molten product from the cutting location, greatly lowering the power requirement. The product is heated up to melting factor after that a gas jet impacts the molten product out of the kerf avoiding the need to increase the temperature of the material any type of further.

Weak products are particularly conscious thermal crack, an attribute made use of in thermal stress fracturing. A light beam is concentrated on the surface triggering localized heating and thermal development. This leads to a split that can after that be directed by moving the beam of light. The split can be relocated order of m/s.

The Main Principles Of Bayside Laser

The splitting up of microelectronic chips as prepared in semiconductor gadget construction from silicon wafers might be performed by the so-called stealth dicing procedure, which runs with a pulsed Nd: YAG laser, the wavelength of which (1064 nm) is well adjusted to the electronic band resource void of silicon (1. 11 e, V or 1117 nm) (laser cutting brisbane). For every one of these, the axes of movement are usually assigned X as well as Y axis. If the reducing head may be controlled, it is marked as the Z-axis. Moving material lasers have a stationary cutting head and also move the material under it. This technique supplies a continuous range from the laser generator to the work surface as well as a single factor from which to get rid of cutting effluent.

This style of machine often tends to have the least beam of light distribution optics however additionally tends to be the slowest. Hybrid lasers supply a table that relocates one axis (normally the X-axis) and also relocates the head along the shorter (Y) axis. This leads to a more continuous beam of light shipment course length than a flying optic machine and might permit an easier light beam delivery system.